Comparison

outsole shapes

time-consuming

adjusts curvature

adjusts curvature

adjusted automatically

pressure

2.Dusty workspace — No dust collection, poor hygiene?

3.High noise — Open design, loud and disruptive?

4.Hard to operate — Needs skilled workers, not beginner-friendly?

5Fixed position — Difficult to move or adjust?

6.Low efficiency — Manual work, slow output?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

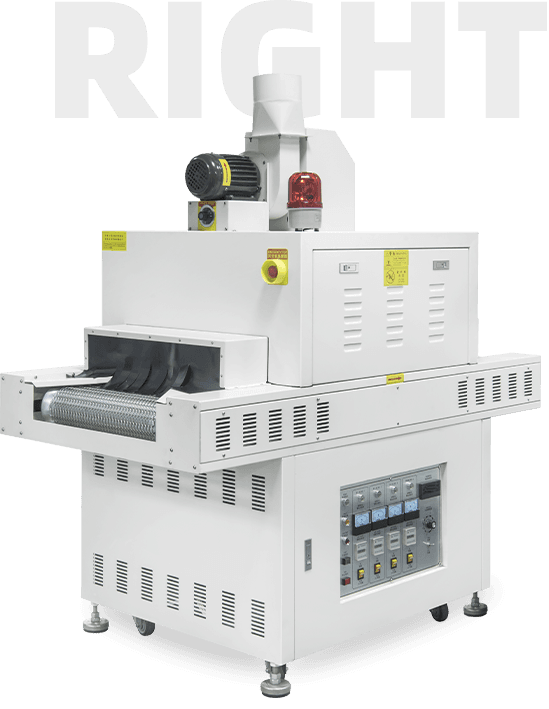

EVA and MD shoe materials. It can also be applied to other fields that

require UV curing, such as material curing and surface treatment in

printing, packaging, electronics and other industries.