Comparison

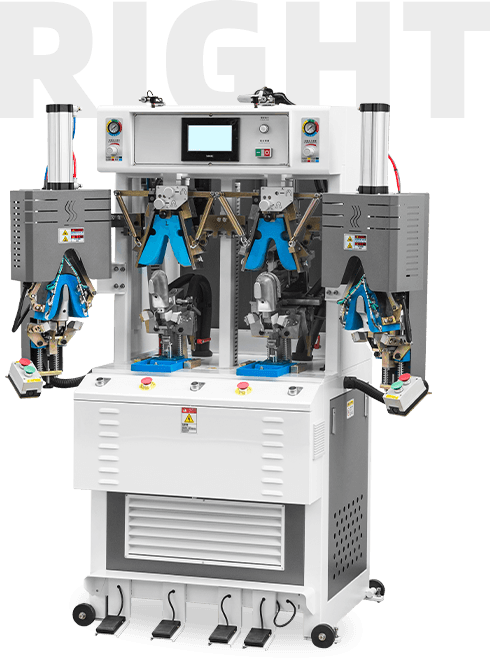

2.Limited claw adjustment, poor fit?

3.Fixed metal mold, uneven heat transfer?

4.Standard heating, slow heat transfer?

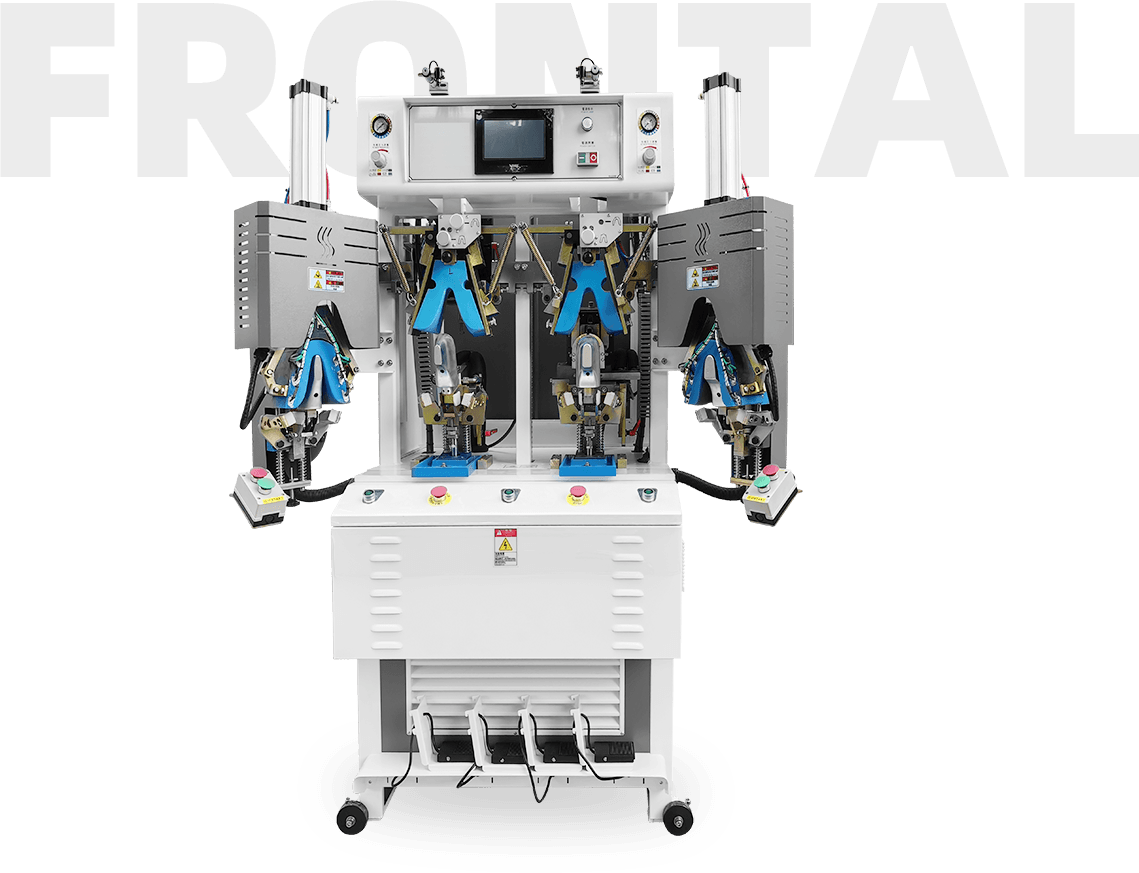

Discover the power of smart lasting automation—stable, efficient, and easy to use.

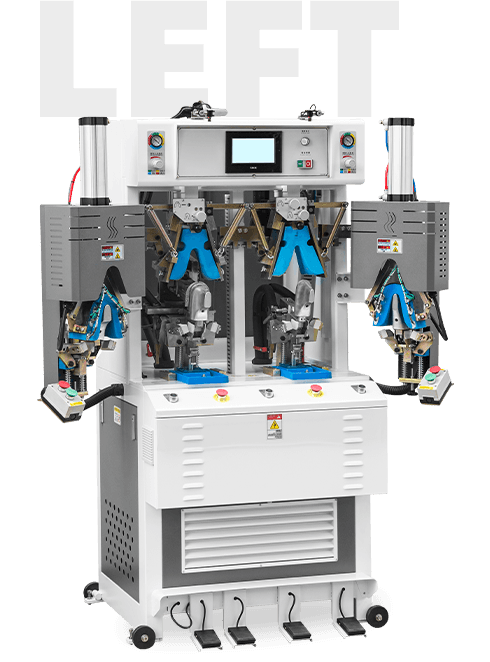

can fold inward and outward folding edge ,Applicable to various

materials of TPU counter shaping.The hot and cold molds are made

of environmentally friendly blue silicone.