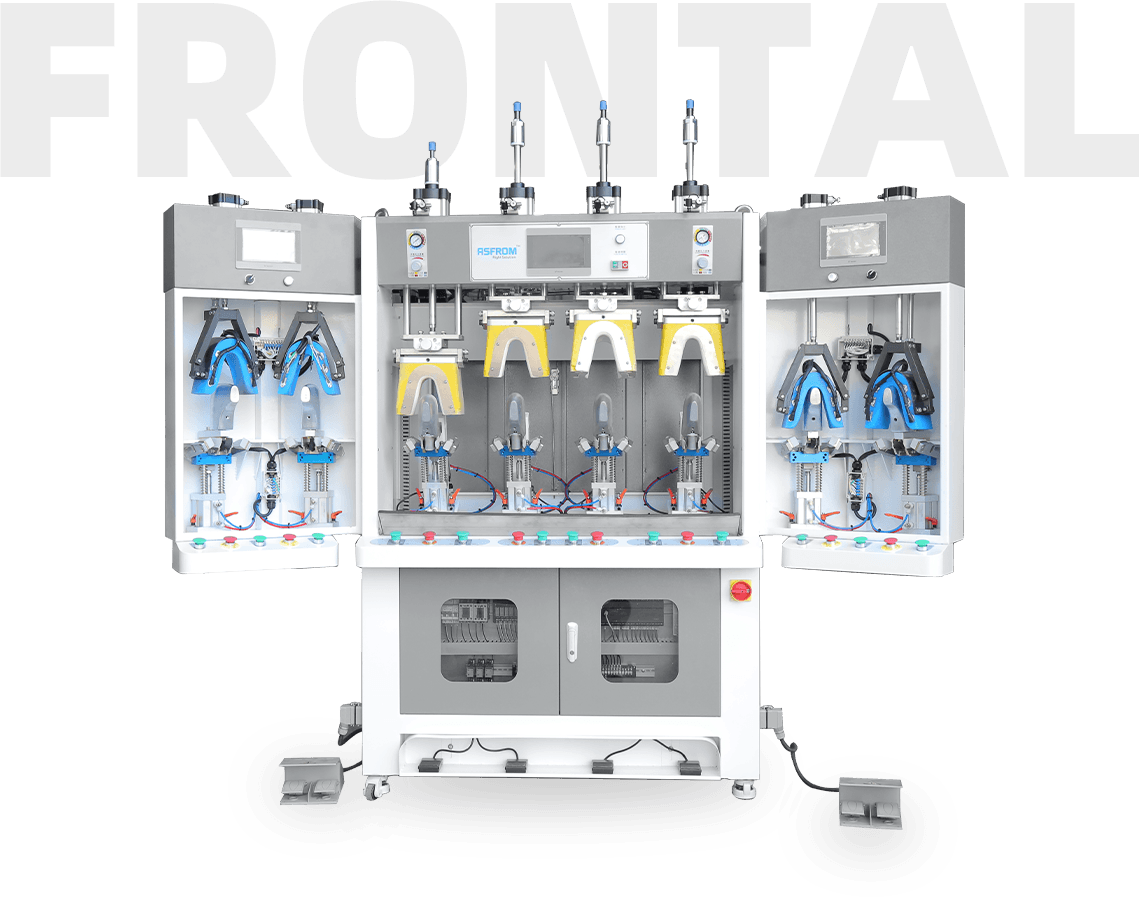

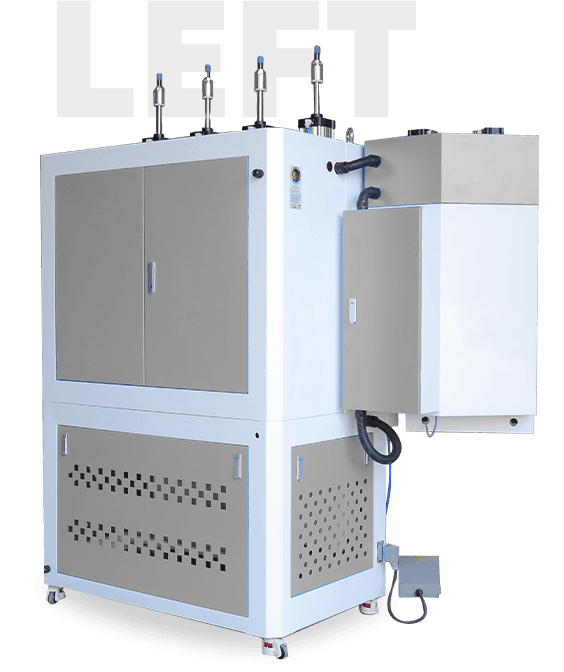

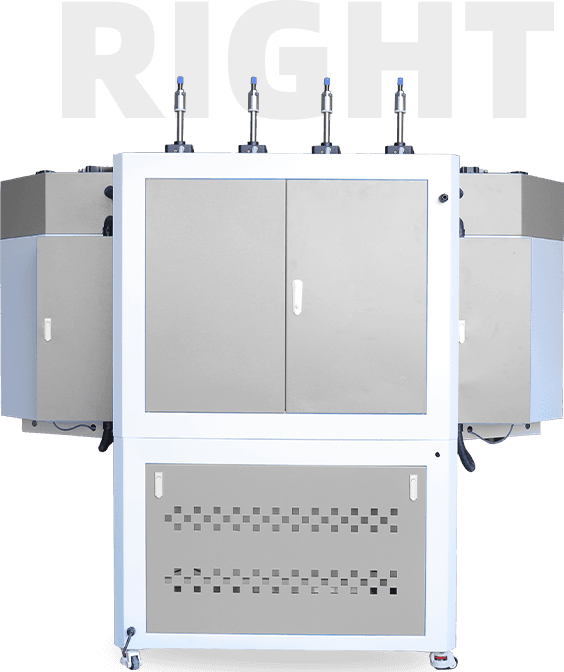

Back Part Molding MachineBack Part Molding Machine

Back Part Molding MachineBack Part Molding Machine

Comparison

integrated airbag design saves time and cost

time-consuming and costly

smooth and precise shaping

directions, perfectly fits shoe shape

2.Fixed position, inconvenient for operators?

3.Mechanical control, low precision?

4.Visual/manual estimation, prone to deviation?

5.Ordinary steel, less durable?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

women's shoes,sports shoes,upper of back part with cold and hot

shaping,as well as shaping the outer and inner folds of hot melt adhesive heels.