Comparison

and does not shift.No deformation,

significantly improve the texture

self-balancing technology

bonding process

Prevent upper damage

and midsole displacement

quality

organization travel, fast

improve the quality of lasting

design tool technology

more match to last

lasting upper doesn’t bounce

,improve lasting quality

replacement and fine-tuning)?

2.Inconsistent quality, shoe toes may deform or shift?

3.Requires skilled workers, high labor cost, low adaptability?

lack professional technical operators to change shoe shape adjustment

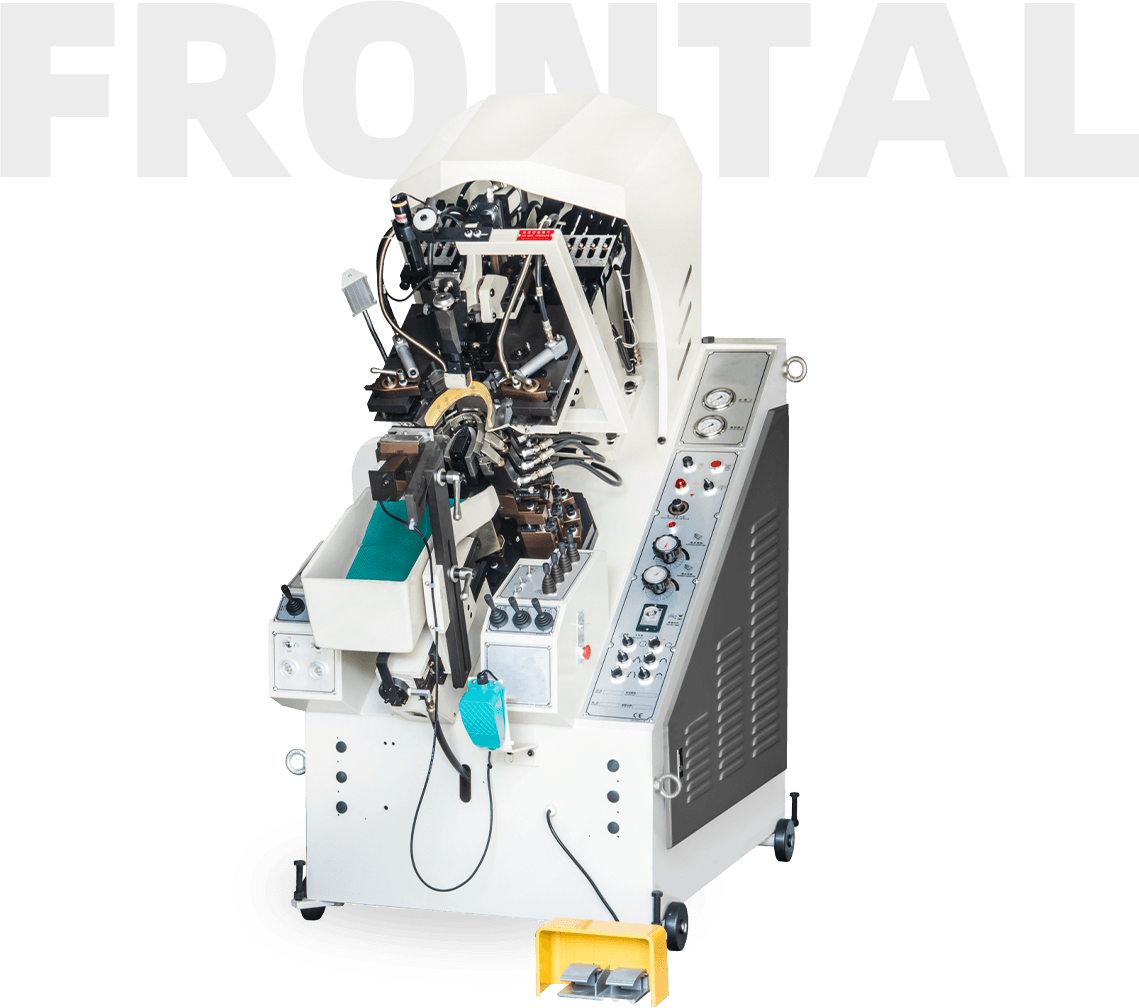

machines. It is suitable for producing high-end men's and women's leather

shoes, sports shoes, casual shoes, skates, labor protection shoes,

Goodyear and other shoe types.

Discover the power of smart lasting automation—stable, efficient, and easy to use.