Skip to content

Efficient cutting and precise protection: The double-knife collaborative working mode of high-speed cutting of the upper knife and rotation of the lower knife can easily and thoroughly remove any type of burrs and flashes. Precise control ensures that the upper, sole or product body will not be damaged during the efficient trimming process, thus improving product quality.

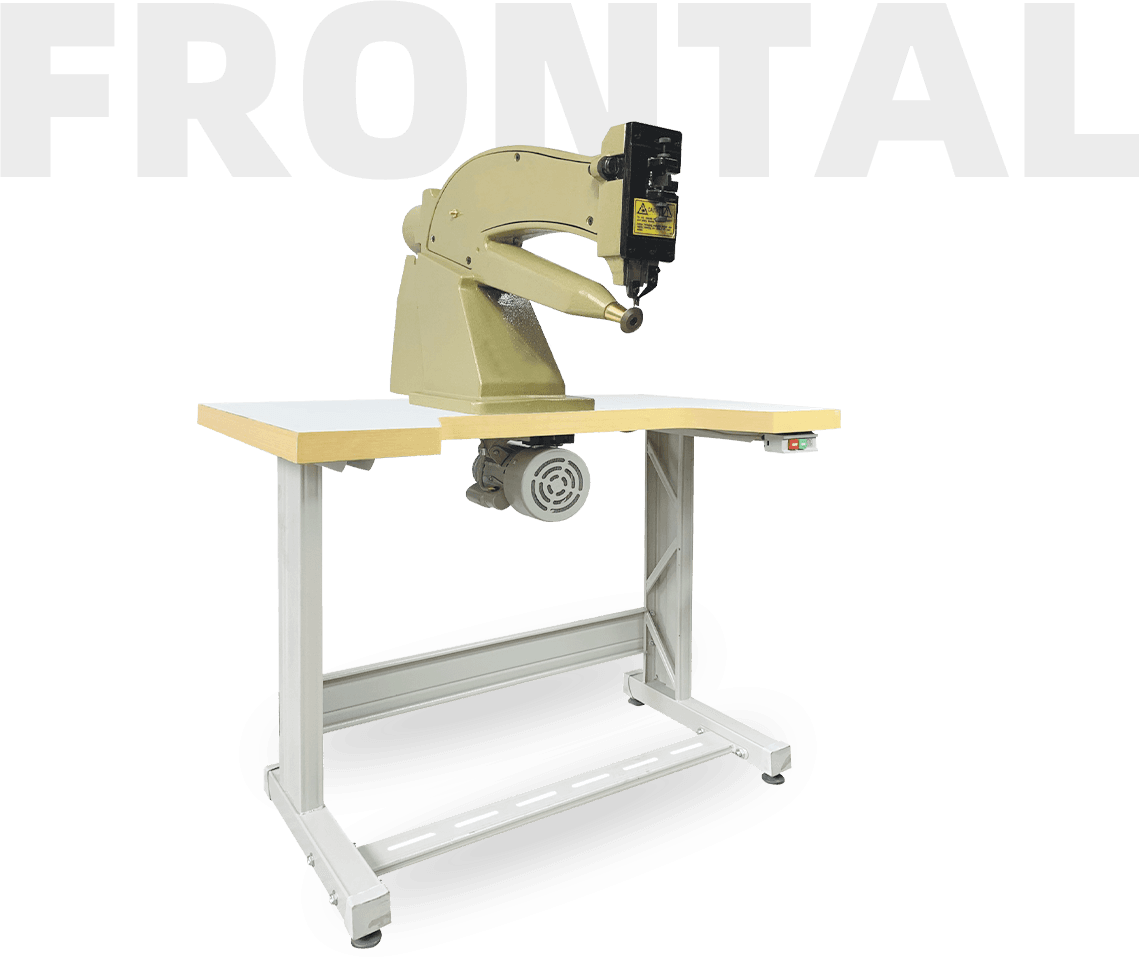

AT-701

Outsole Trimming Machine ---

New product under development.....

Outsole Trimming Machine

Shoe forming machine

Knife Cooling System: Built-in cooling device effectively reduces the heat generated by the tool during high-speed cutting, extends the tool life and prevents thermal damage to the material.

AT-701

Knife sharpening device: Equipped with knife sharpening equipment, it is convenient for operators to grind and maintain the knives on the machine quickly and conveniently, keeping the blades sharp and ensuring continuous trimming quality and efficiency.

AT-701

Special machine for boots: A vibration bracket and a rotating bracket can be installed at the front end of the lower shaft. By adjusting the vibration frequency and rotation angle of the bracket, the operator can easily find and fix the best trimming angle and position, so as to efficiently and accurately complete the complex trimming tasks of the inner lining or excess edges of the boot shaft.

Efficient cutting and precise protection: The double-knife collaborative working mode of high-speed cutting of the upper knife and rotation of the lower knife can easily and thoroughly remove any type of burrs and flashes. Precise control ensures that the upper, sole or product body will not be damaged during the efficient trimming process, thus improving product quality.

AT-701

Outsole Trimming Machine ---

New product under development.....

Outsole Trimming Machine

Shoe forming machine

Knife Cooling System: Built-in cooling device effectively reduces the heat generated by the tool during high-speed cutting, extends the tool life and prevents thermal damage to the material.

AT-701

Knife sharpening device: Equipped with knife sharpening equipment, it is convenient for operators to grind and maintain the knives on the machine quickly and conveniently, keeping the blades sharp and ensuring continuous trimming quality and efficiency.

AT-701

Special machine for boots: A vibration bracket and a rotating bracket can be installed at the front end of the lower shaft. By adjusting the vibration frequency and rotation angle of the bracket, the operator can easily find and fix the best trimming angle and position, so as to efficiently and accurately complete the complex trimming tasks of the inner lining or excess edges of the boot shaft.