Comparison

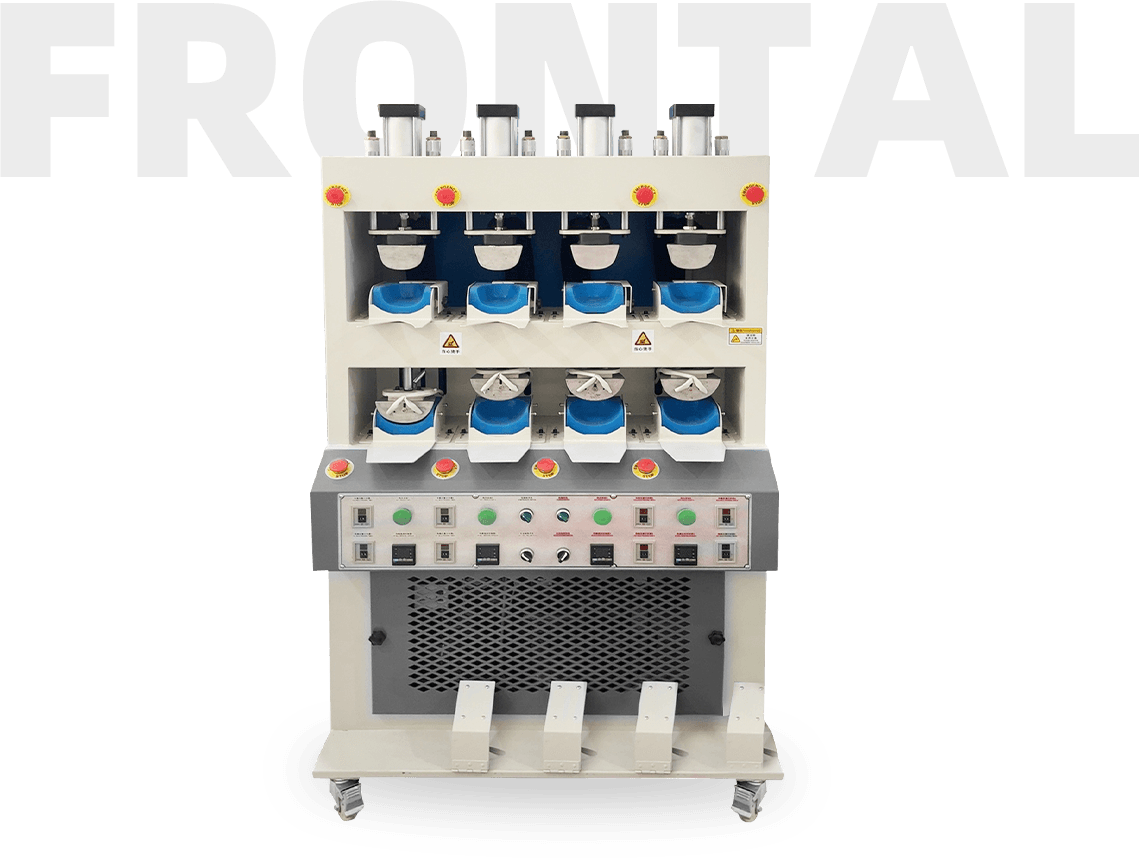

stable shaping, reduced maintenance

distribution, unstable shaping results

pressing, consistent & standardized toe shape

efficiency, supports mass production

2.Longer shaping time, limited output?

3.Higher energy consumption, less efficient cooling?

4.Difficult adjustment for different shoe types; time-consuming setup?

5.Higher long-term cost due to downtime, rework, and labor?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

children's shoes, sports shoes, casual shoes, functional shoes, etc.