Hot Melt Spray Glue Machine

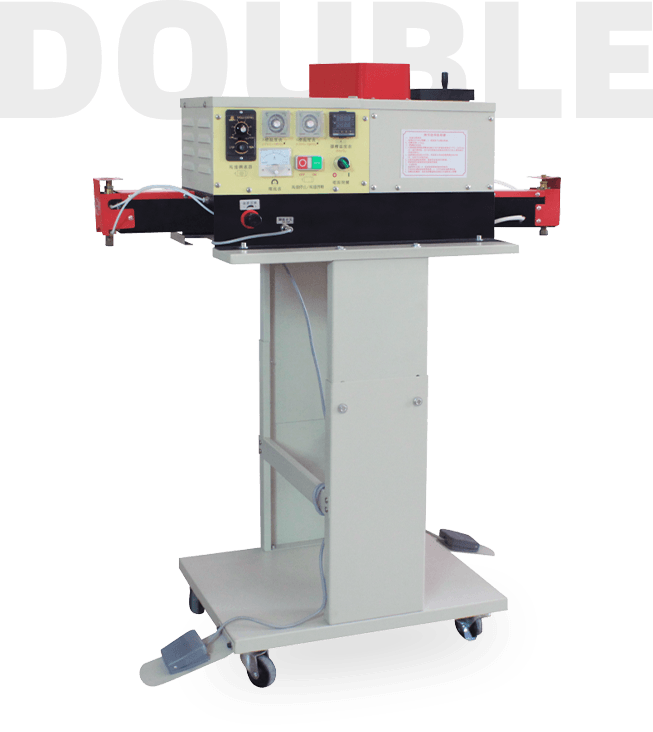

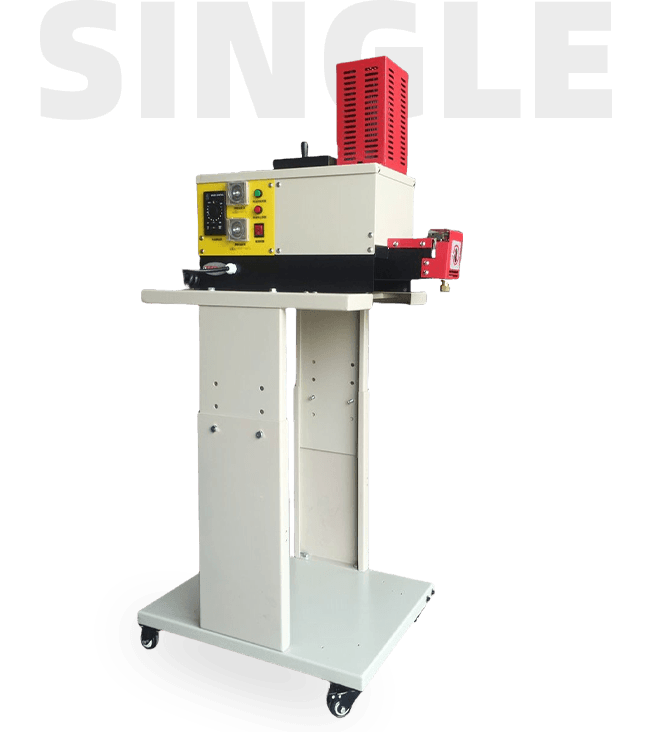

Comparison

outsole shapes

time-consuming

adjusts curvature

adjusts curvature

adjusted automatically

pressure

2.Dusty workspace — No dust collection, poor hygiene?

3.High noise — Open design, loud and disruptive?

4.Hard to operate — Needs skilled workers, not beginner-friendly?

5Fixed position — Difficult to move or adjust?

6.Low efficiency — Manual work, slow output?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

on the substrate. It is widely used in different manufacturing industries such

as shoemaking, packaging, wood industry, textile industry, toy industry,

leather shoes industry, sanitary products, electrical appliances, etc.