Skip to content

High wear-resistant diamond wheel: Using imported high wear-resistant diamond wheel as the core abrasive tool can greatly extend the service life of key wearing parts and reduce replacement frequency and cost.

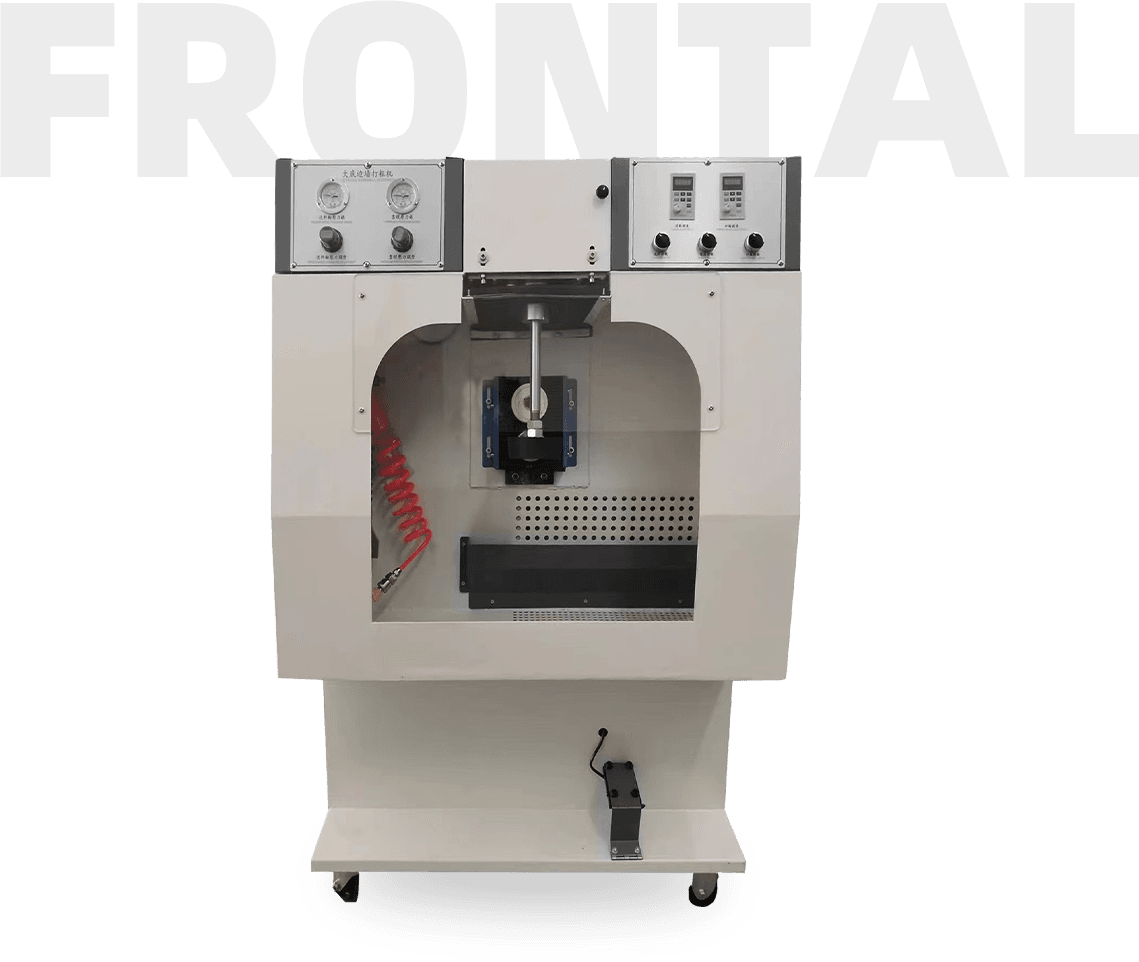

AFL-8832E

Buffing Machine ---

New product under development.....

Buffing Machine

Shoe forming machine

Automatic feeding: The operation is simple and intuitive. The user only needs to place the material to be processed at the feed port, and the equipment can automatically feed and perform roughing operations.

AFL-8832E

Quick Adjustment: Equipped with advanced adjustable automatic rise/fall function, it can quickly adjust the roughing depth (thickness), significantly improving the operation speed and overall work efficiency, saving valuable time.

AFL-8832E

Intelligent protection device: Imported high-precision descent limit switch is installed to intelligently control the descent stroke, effectively preventing excessive downward pressure and unnecessary wear of parts such as the feeding rubber wheel, ensuring the long-term stable operation of the core components of the equipment and maintaining processing accuracy.

High wear-resistant diamond wheel: Using imported high wear-resistant diamond wheel as the core abrasive tool can greatly extend the service life of key wearing parts and reduce replacement frequency and cost.

AFL-8832E

Buffing Machine ---

New product under development.....

Buffing Machine

Shoe forming machine

Automatic feeding: The operation is simple and intuitive. The user only needs to place the material to be processed at the feed port, and the equipment can automatically feed and perform roughing operations.

AFL-8832E

Quick Adjustment: Equipped with advanced adjustable automatic rise/fall function, it can quickly adjust the roughing depth (thickness), significantly improving the operation speed and overall work efficiency, saving valuable time.

AFL-8832E

Intelligent protection device: Imported high-precision descent limit switch is installed to intelligently control the descent stroke, effectively preventing excessive downward pressure and unnecessary wear of parts such as the feeding rubber wheel, ensuring the long-term stable operation of the core components of the equipment and maintaining processing accuracy.