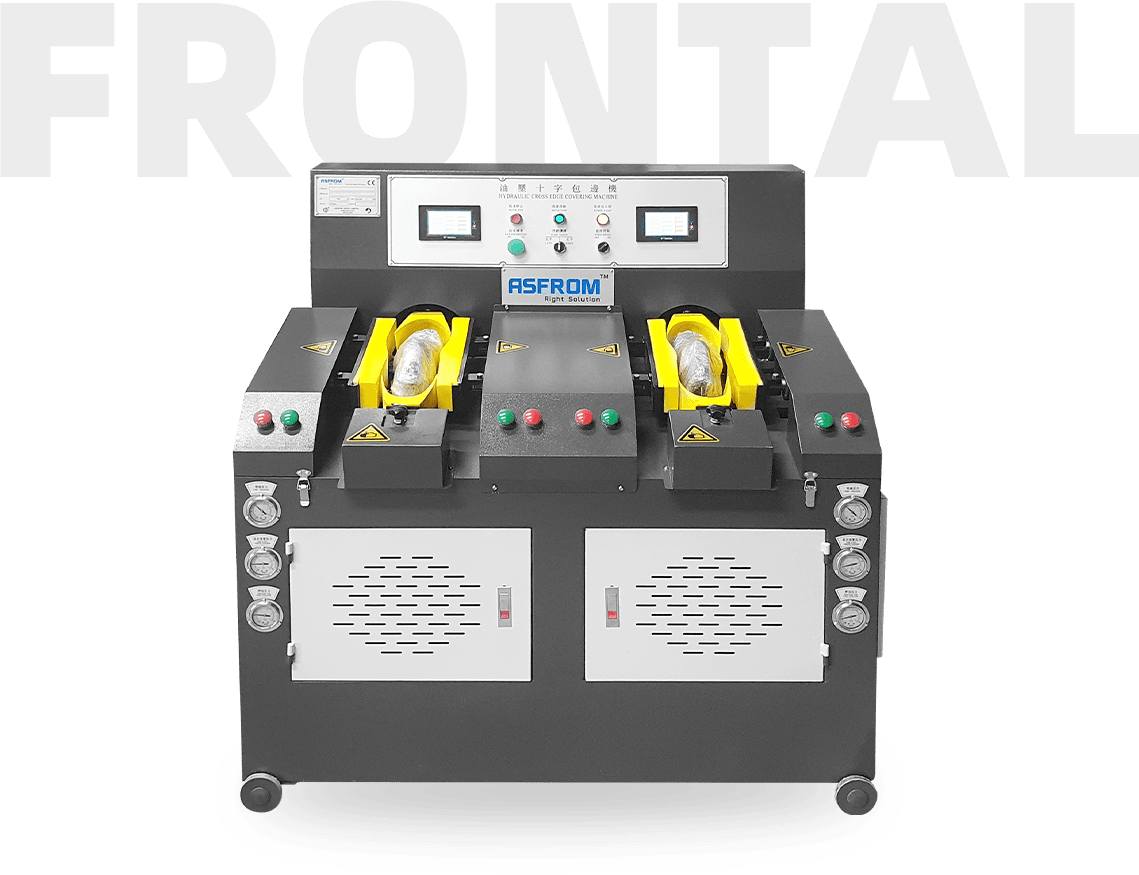

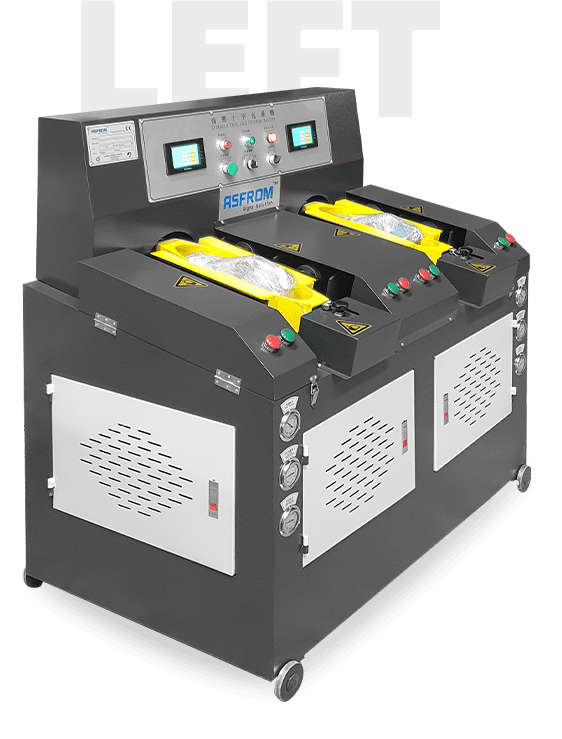

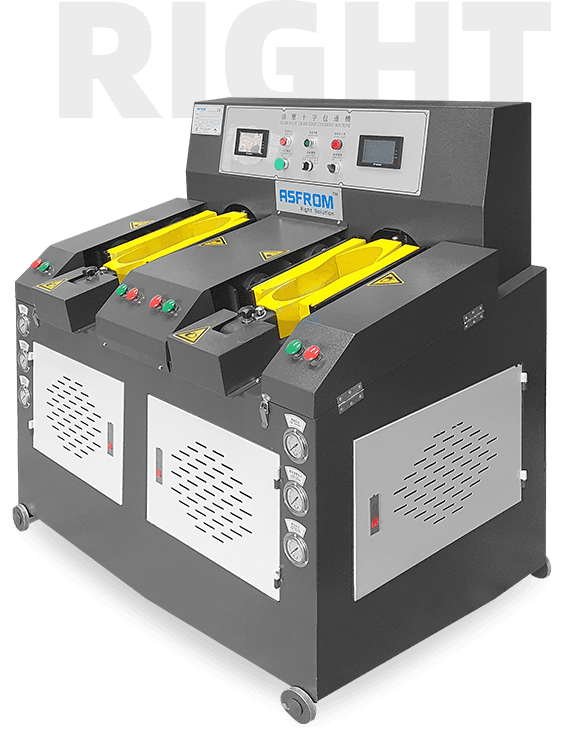

Double Station Hydraulic Cross Edge Covering Machine

Double Station Hydraulic Cross Edge Covering Machine

Comparison

2.Circuit and system structure are complicated, causing longer downtime during repair?

3.High-temperature hydraulic operation may reduce service life and cause instability?

4.High dependence on skilled labor increases training costs and reduces productivity?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

achieve bonding effect.