Comparison

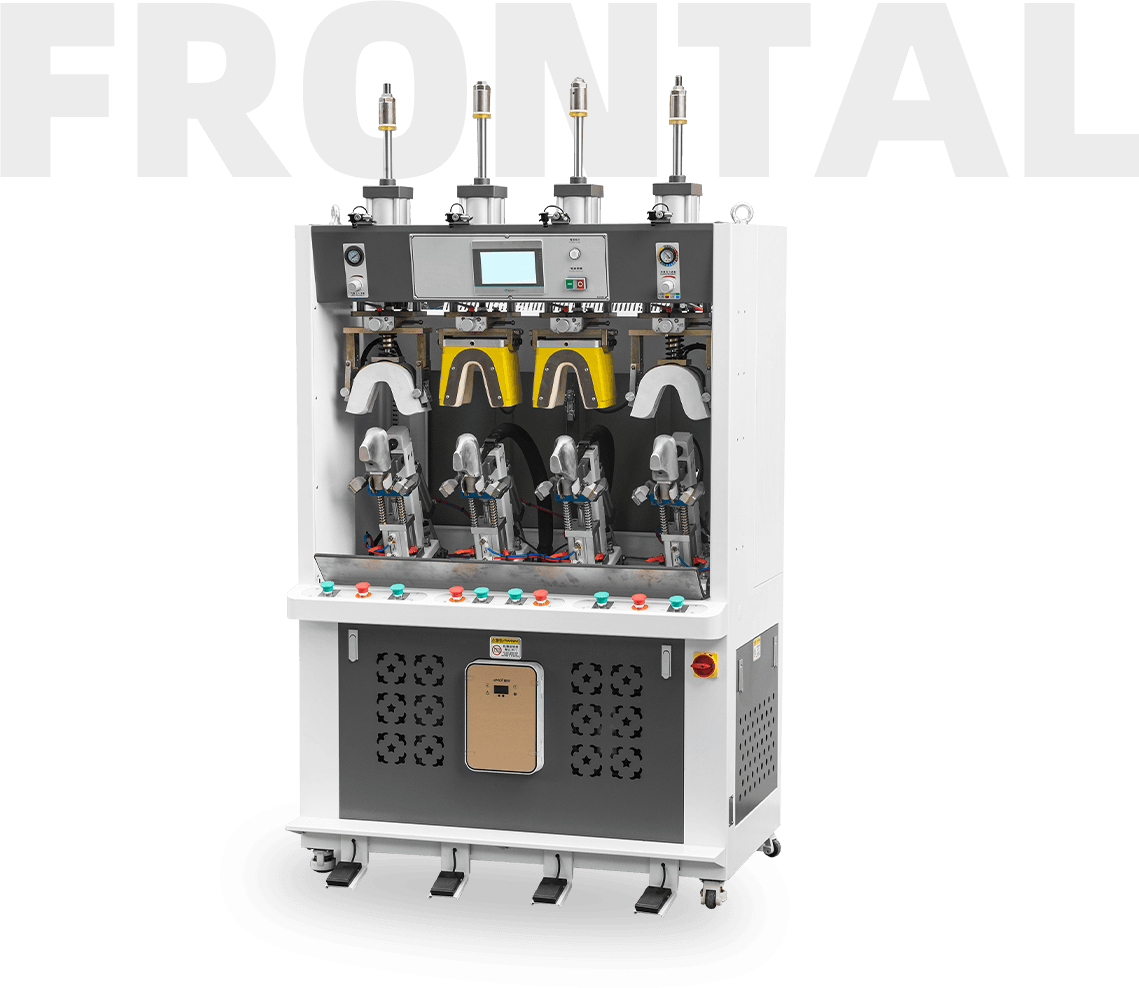

mold & integrated airbag cold mold; only inner

cold mold needs replacement, ensures full shaping

easy to stick to upper

multi-directional adjustment, upper adheres

tightly to last

inconsistent results

energy-saving compressor, stable operation

2.Mechanical or simple button, low precision?

3.Manual visual positioning, high deviation?

4.Single/double station, limited output?

5.Standard steel parts, prone to wear?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

men's and women's shoes, sports shoes, and uppers and heels.

The hot mold uses fast heat-conducting silicone mold, which heats up

quickly, making the hot melt rubber sheet and the inner wrapping fit better.