Comparison

loading/unloading with minimal adjustment.

requires frequent adjustments.

aluminum molds; shaping effect is more

accurate and consistent.

achieve precise shaping, especially for hot melt

adhesive.

the last; curve angle and depth are adjustable

for better shaping.

between upper and last, shaping not tight enough.

2.Cooling mold is fixed, making operation and positioning less flexible?

3.Higher labor intensity, slower cycle time, inconsistent results?

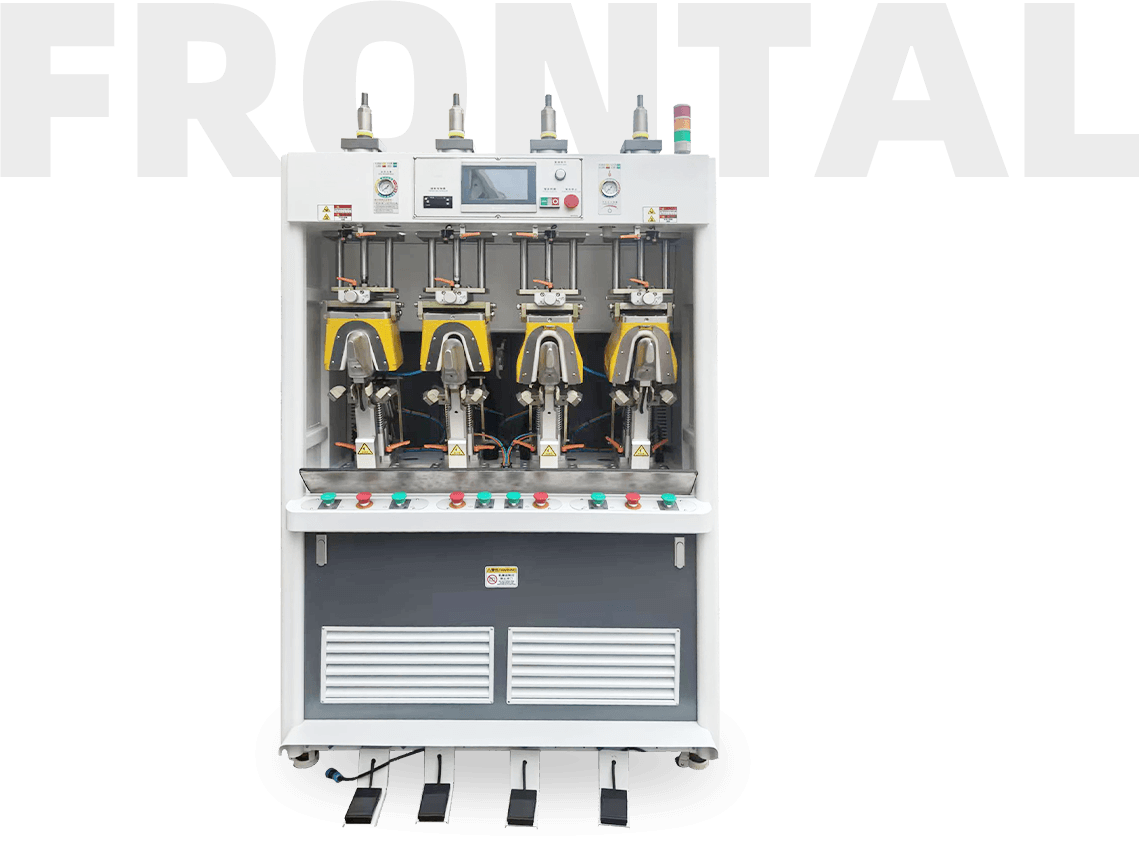

Discover the power of smart lasting automation—stable, efficient, and easy to use.

women's shoes,sports shoes,upper of back part with cold and hot

shaping,as well as shaping the outer and inner folds of hot melt adhesive heels.