Comparison

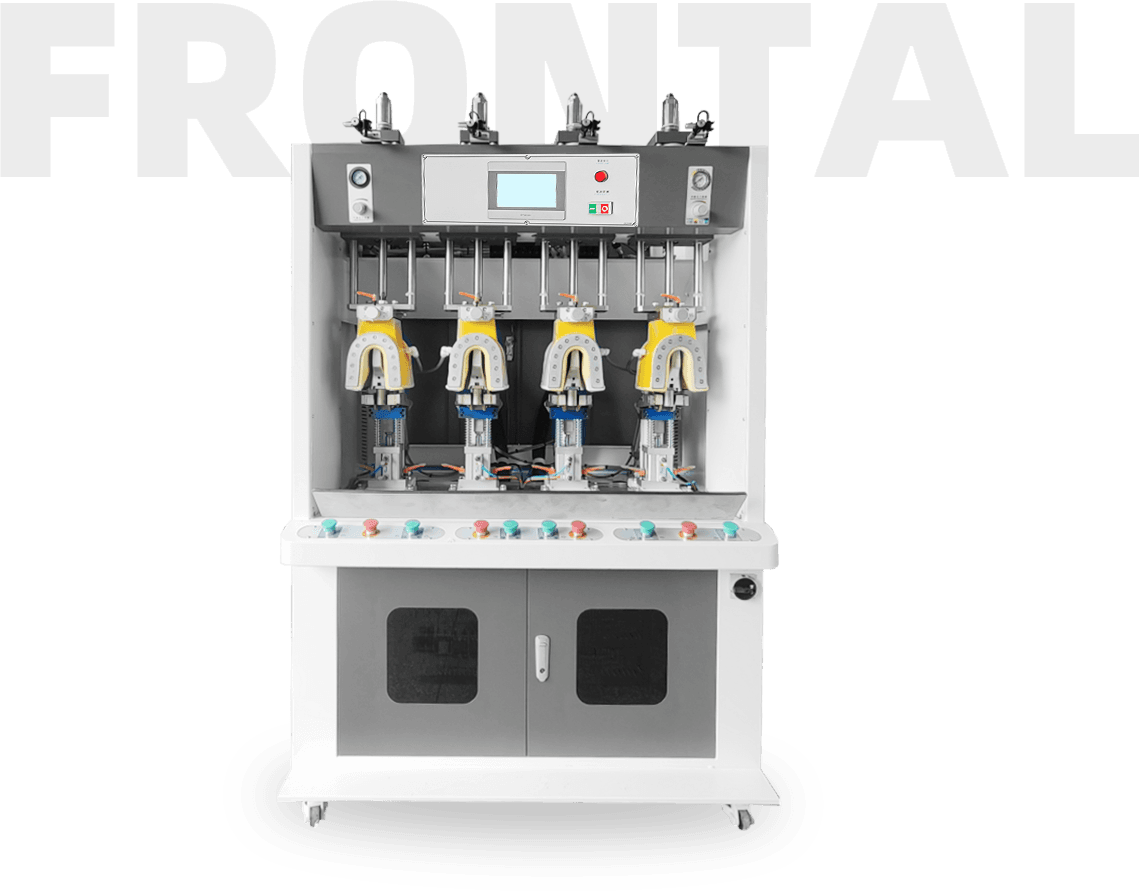

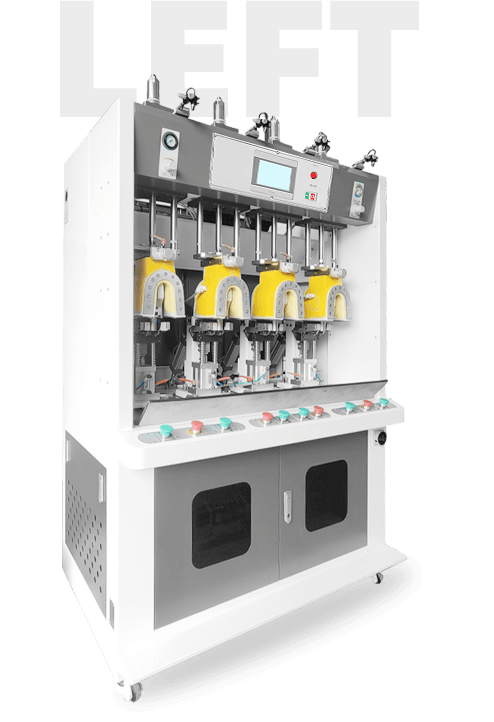

replacement, ensures full air pressure shaping,

achieving uniform and smooth heel molding.

shaping effect is unstable, especially for complex

shoe lasts.

multi-directional and wide-range adjustment,

making uppers tightly fit the last for all shoe shapes.

time-consuming when changing shoe types.

eco-friendly refrigerants, rapid cooling at -15°C,

ensuring faster shaping and stable operation.

eduction, unstable for continuous production.

2.Manual or button control, difficult to precisely control molding time and temperature?

3.Lacks precise positioning system, easy to cause heel deviation?

4.Iron or simple fixtures, prone to deformation, shorter service life?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

activates the hot melt adhesive wrapped inside the heel

with high-temperature hot air.There are various specifications

available for selection.