Skip to content

2.Uniform cooling effect: The closed direct cooling refrigeration system is adopted, with a fast cooling speed, reaching -15°C in five minutes, and a good shaping effect, ensuring that the toe cooling process is uniform and stable.

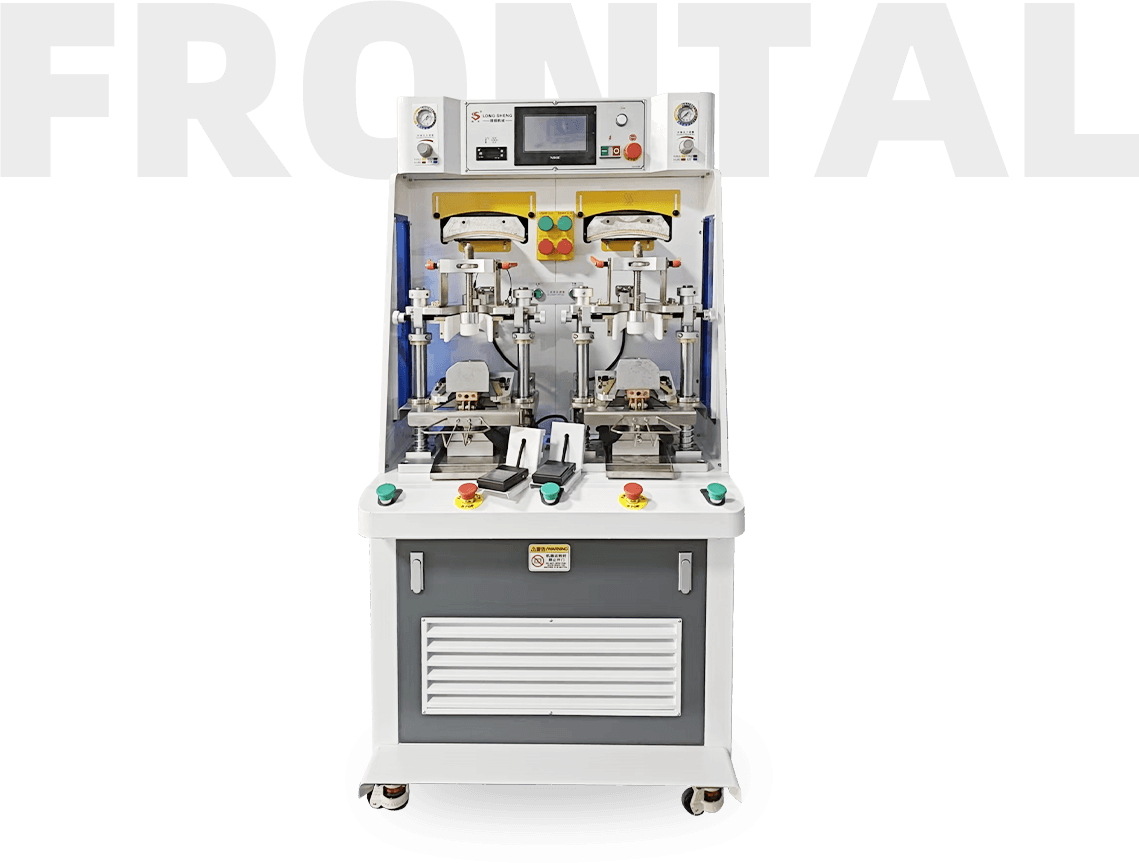

ACH-712E-2C2H

3. Mold system: The hot mold can simultaneously heat the steam to soften the upper, making the upper more fitting, more elastic and shiny. The cold mold fixture uses a Teflon strap group with a last mold, which is made according to the customer's last, with an accuracy of 98%. The mold is fixed with a buckle, and the mold can be quickly replaced. It only takes five or six minutes for a skilled worker to disassemble and assemble a set of molds.

New product under development.....

Toe Cap Molding Machine

2.Uniform cooling effect: The closed direct cooling refrigeration system is adopted, with a fast cooling speed, reaching -15°C in five minutes, and a good shaping effect, ensuring that the toe cooling process is uniform and stable.

ACH-712E-2C2H

3. Mold system: The hot mold can simultaneously heat the steam to soften the upper, making the upper more fitting, more elastic and shiny. The cold mold fixture uses a Teflon strap group with a last mold, which is made according to the customer's last, with an accuracy of 98%. The mold is fixed with a buckle, and the mold can be quickly replaced. It only takes five or six minutes for a skilled worker to disassemble and assemble a set of molds.

New product under development.....

Toe Cap Molding Machine

(For 2 Colds & 2 Hots)

Shoe forming machine

1. Hot mold steam system: The steam heating system is located above the machine, with a fast heating speed, reaching 120 degrees Celsius in 15 minutes, and the temperature fluctuation is only 2-5 degrees Celsius. It is suitable for different materials and has excellent results.

Toe Cap Molding Machine

(For 2 Colds & 2 Hots) ---

ACH-712E-2C2H

ACH-712E-2C2H