what we do…

EVA FOAMING LINE MACHINERY

EVA Foam machine

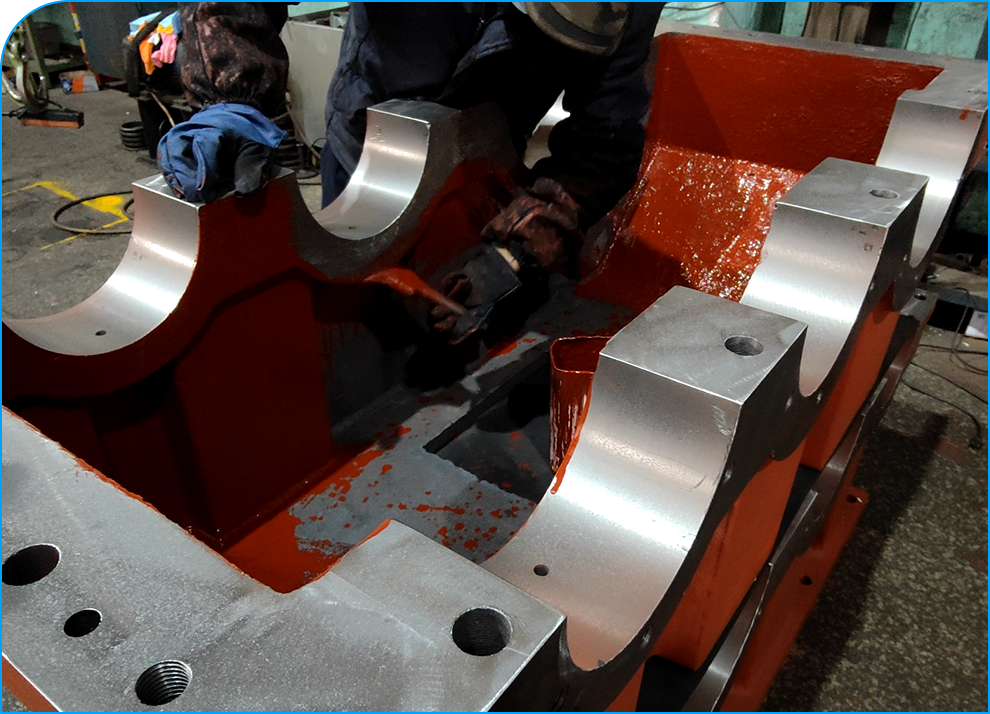

KNEADER MIXER MACHINE

1.Milling Chamber It consists of M-shaped milling slot and two side plates The slot is made of high-quality abrasion-resistant steel. The jacketed structure is for cooling or heating. The internal surface is coated with hard chrome.

2.Thermal Resistor The central base of the mixing chamber is designed with plug-in thermal resistance sensor, which is connected with electric control system to monitor and control the mixing temperature.

3.Agitator Shaft It is made of train shaft materials with high precision treatment. The driving force is good. It has long and short rib rotors. There is a hole connecting through with the inner cavity of the rib for better cooling effect. The rid peak and end face build-up weld is made of abrasive hard metal alloy. It is polished after grinding and hard chrome plating.

4.Heating and Cooling System: A set of pipeline system is adopted to cool or heat the media (water, steam or oil). It connects with rotor rib, mixing chamber and pressing ram in three ways to cool or heat the materials by circulation.

Bucket Conveyor Machine

1.This machine is suitable for installation between the kneader mixer and open mixing mill, enabling automatic conveying of mixed materials to the open mixing mill for efficient inter-process connection.

2.It replaces manual feeding, eliminating the cumbersome process of manual handling and feeding, significantly saving labor costs and greatly improving production efficiency.

3.The frame is constructed with section steel welding assembly, featuring high structural strength. It ensures stable and reliable operation of the equipment at all times, effectively avoiding feeding precision deviations caused by vibration.

4.The hopper is made of stainless steel plate assembly, boasting excellent wear resistance and corrosion resistance. It can effectively extend the service life of the equipment, with convenient maintenance and simple operation.

Open Mixing Mill Machine

1. The roller material is vanadium-titanium alloy chilled cast iron and the roller structure is heated or cooled by drilling or hollowing to make the roller surface temperature uniform;

2. Hard surface reducer for transmission system, compact structure, low noise and high efficiency;

3. The roller adopts self-aligning bearing, low energy consumption, convenient maintenance, long service life;

4.The machine is equipped with hydraulic and electric power reverse braking device.

5. The lubrication system adopts integrated circulation lubrication to reduce oil leakage.

Tapered Twin-screw Extruder

1. Save manpower and energy.

2. It can be produced continuously and automatically.

3. The uniquely designed conical screw and extruding chamber can twist the whole batch of rubber materials after mixing into it without material accumulation and residual material.

4. Good cooling efficiency, high cooling efficiency of the rubber compound.

5. The feed inlet is wide and convenient for feeding, convenient material cleaning, simple maintenance and long machine life.

Water-Cooled Slicing Machine

1. 1.Roller Material: Constructed from stainless steel, it boasts fast cooling speed and corrosion resistance—extending the equipment’s service life while ensuring optimal cooling performance.

2.Material Cutting System: Equipped with a clutch and time control mechanism, it enables precise regulation of cutting length, thus guaranteeing the dimensional accuracy of sheet materials.

3.Dual-Layer Structure: The dual-layer design reduces the equipment’s floor space in the workshop and enhances overall space utilization efficiency.

Hydraulic Press Machine

1. Automatic ascending, bumping, pressurization and descending operations.

2. High speed ascending, pressure retaining for better product quality.

3. Quick release valve for quick descending but incorporates adjustable speed.

4. Depressurization can be adjusted according to products thickness.

5. Special designed platens for even heating area.

6. The above features can be incorporated in, automatic and semi-automatic machines.

About EVA

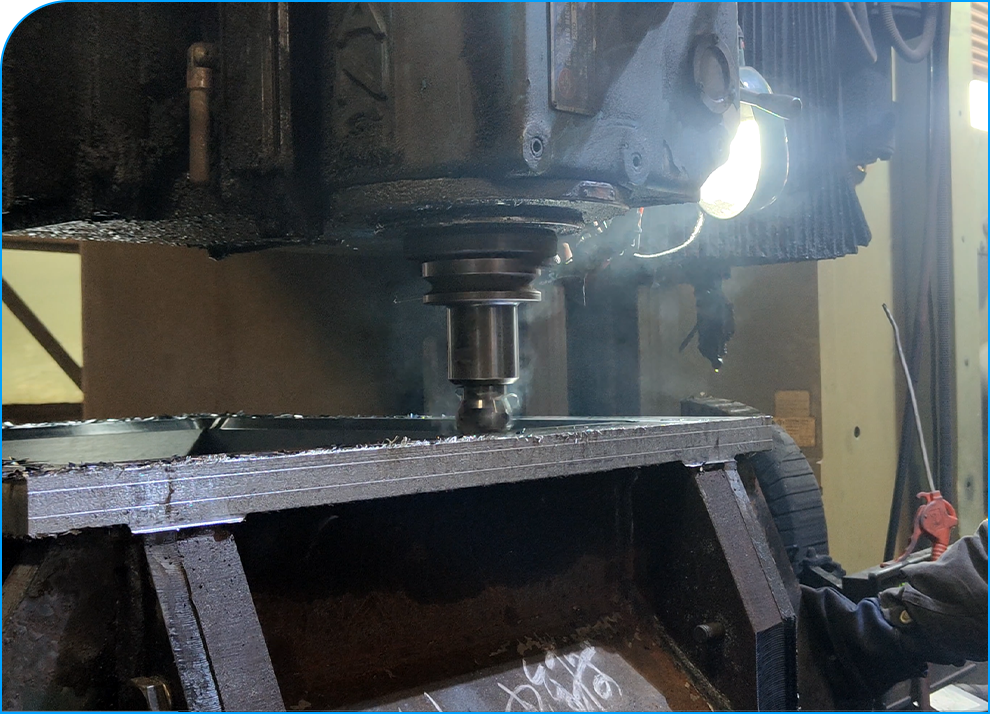

Regarding EVA Foam Machine Manufacturing Plants

We are a leading EVA Foam Machine manufacturer, dedicated to strict quality control and considerate customer service. Our factory is equipped with advanced production lines and experienced staff who ensure every machine meets high standards. We are always available to discuss your requirements and guarantee full customer satisfaction, providing reliable solutions for EVA foam production.