This machine uses a clamping mechanism,which can evenly spread all parts during leather shaping,reducing the occurrence of defective products.

It can adjust the required stroke depth according to the size of the upper area, and adjust the required bearing capacity, feeding speed, shaping time, shaping temperature, and lower knife and top material pressure according to the material characteristics to make the upper shaping warpage more perfect.

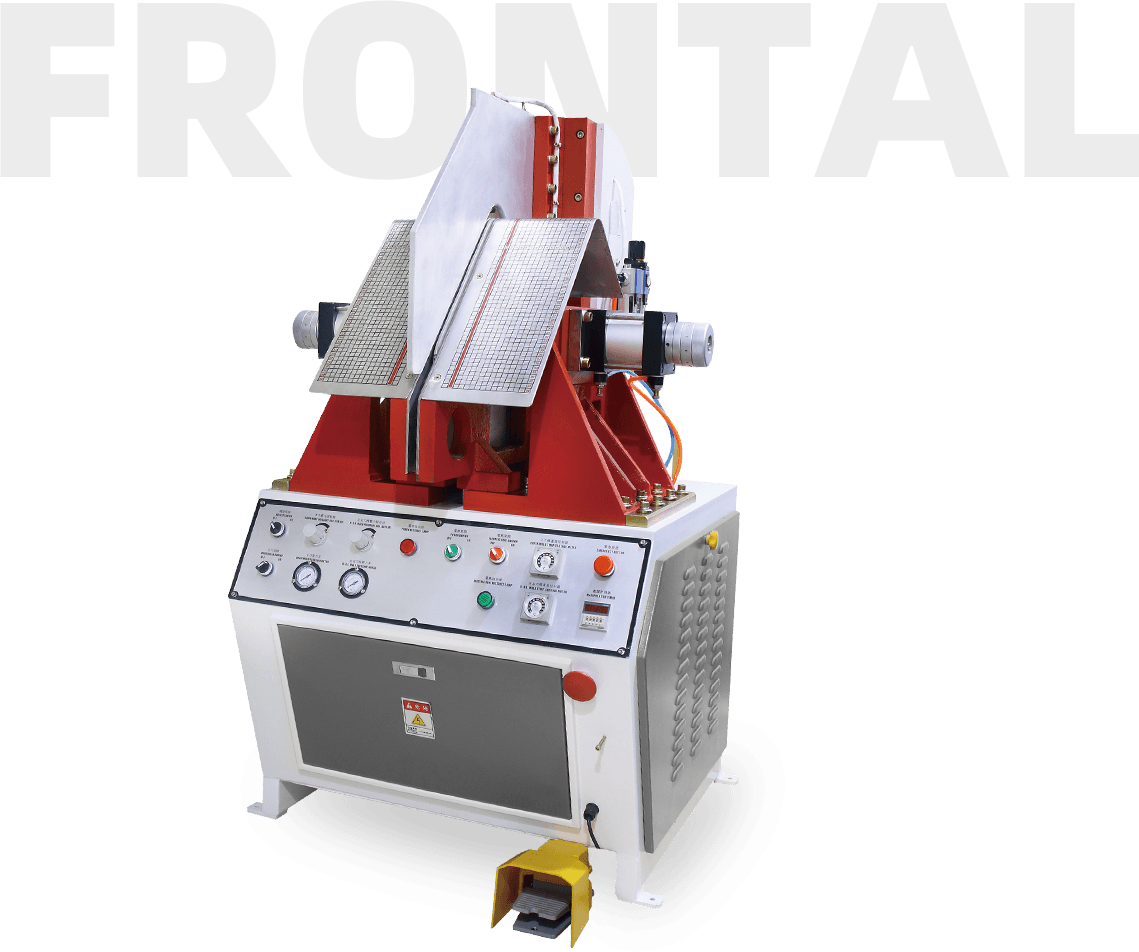

Machine (Hydraulic Type ) ---

Machine (Hydraulic Type )

This machine adopts air and oil pressure parallel design, the air pressure is sufficient and the material feeding is stable

This machine uses electric heating, air pressure operation, and is easy to adjust.

Comparison

outsole shapes

time-consuming

adjusts curvature

adjusts curvature

adjusted automatically

pressure

2.Dusty workspace — No dust collection, poor hygiene?

3.High noise — Open design, loud and disruptive?

4.Hard to operate — Needs skilled workers, not beginner-friendly?

5Fixed position — Difficult to move or adjust?

6.Low efficiency — Manual work, slow output?

Discover the power of smart lasting automation—stable, efficient, and easy to use.