Comparison

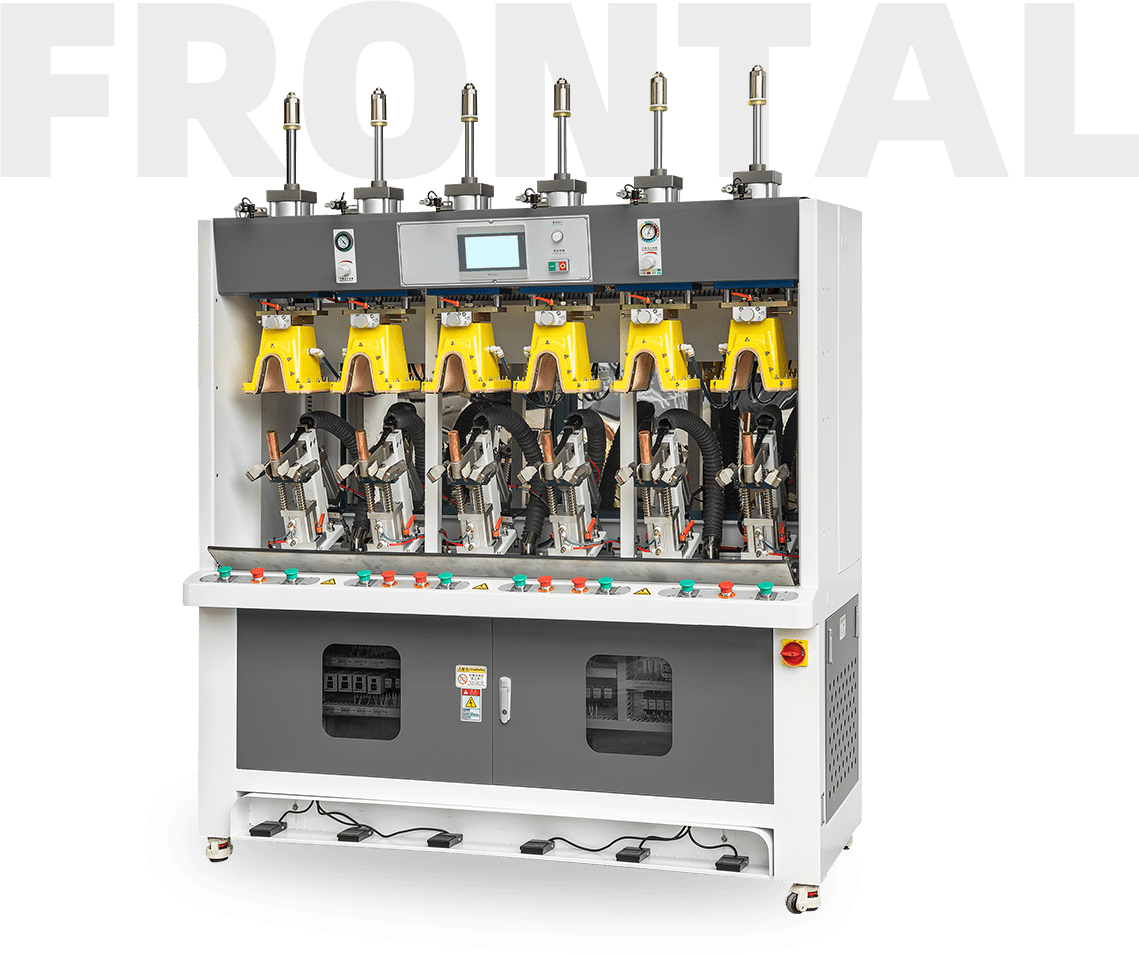

pressure shaping, delivering smooth and

accurate heel molding.

pressure distribution is uneven, often causing

wrinkles or deformation.

adjustable in all directions for precise fitting

to the last.

adapt to various shoe shapes.

refrigerant, rapid cooling down to -15°C, stable

and energy-saving.

control, low efficiency.

2.Manual switches, no precise control?

3.Rough positioning, prone to deviation?

4.Normal fixtures, wear easily, frequent replacement needed?

5.Standard single-function design, difficult to expand?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

hot melt adhesive materials.